HDF vs. MDF: Who Wins?

When it comes to building materials, designers and builders are always looking for options that combine strength, durability, and a polished aesthetic. High-Density Fiberboard (HDF) has become the go-to solution for many, especially when compared to its more common counterpart, Medium Density Fiberboard (MDF). At Muskoka Timber Mills, we’ve made the decision to exclusively offer HDF due to its superior properties and versatile applications. In this blog, we’ll dive into what HDF is, why it outperforms MDF, and why both builders and designers love working with it.

What is HDF?

Fiberboard is an engineered wood product made by breaking down wood into fibers and then combining those fibers with resins and heat to form dense panels. It is at the front end of the chipper in the grinding process, when the knives are much sharper, creating a finer raw material which allows is to be more much dense, by packing in more material.

It’s commonly used in furniture, cabinetry, paneling, and construction because it's smooth, consistent, and more affordable than solid wood. There are different types of fiberboard, each classified by density:

-

Low-Density Fiberboard (LDF)

-

Medium-Density Fiberboard (MDF)

-

High-Density Fiberboard (HDF)

High-Density Fiberboard (HDF) is the strongest and most durable type of fiberboard. It's made using the same basic process as MDF, but it's compressed under much higher pressure, resulting in a denser, harder, and more impact-resistant board. HDF typically has a density above 800 kg/m³, compared to around 600–700 kg/m³ for MDF. While MDF is commonly used for a variety of projects, HDF takes things a step further by offering enhanced performance and durability.

Why is HDF better than MDF?

-

Superior Strength: HDF’s high-density composition makes it significantly tougher than MDF. It stands up to frequent handling and jobsite wear and tear, making it ideal for both small trim jobs and large-scale installations. Whether it’s ceilings, walls, or cabinetry—HDF performs under pressure.

-

Moisture Resistance: HDF is far less prone to swelling or warping when exposed to humidity compared to MDF. This makes it a smart choice for kitchens, bathrooms, and other moisture-prone areas. (Note: HDF is not waterproof—an exterior-grade paint or coating is always recommended for added protection.)

-

Structural Reliability: Because it resists chipping, splitting, and sagging, HDF provides a solid base for installations that need to stay put. Its superior screw-holding ability makes it a trusted material for secure, long-lasting results in everything from built-ins to wall and ceiling cladding.

-

Clean, Smooth Finishing: The ultra-fine surface of HDF allows for crisp paint lines and a flawless finish. Whether you’re going for a bold colour or a subtle tone, HDF delivers a clean, high-end look without grain inconsistencies or blotching.

-

Eco-Conscious Choice: HDF is manufactured using recycled wood fibers and byproducts, making it a more sustainable alternative to traditional lumber. Designers and builders who prioritize green building practices appreciate its lower environmental footprint.

-

Reduced Waste on Site: HDF’s durability means fewer breakages and damaged boards during transport or install—saving time, money, and material waste on the job. It’s a dependable material that holds up well during every phase of the project.

-

Finish Flexibility: HDF accepts a wide range of paints and coatings with ease—matte, satin, gloss, or fully custom. It’s easy to sand, prime, and coat, so whether you're matching an existing aesthetic or starting fresh, HDF adapts beautifully.

-

Versatile Applications: From wall cladding and ceiling panels to trim, cabinetry, and custom millwork—HDF can be used across a broad range of interior applications. It delivers the premium appearance of solid wood, minus the premium price and maintenance concerns.

Specifications

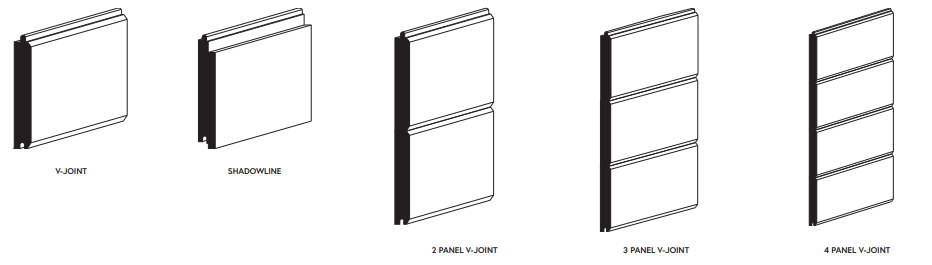

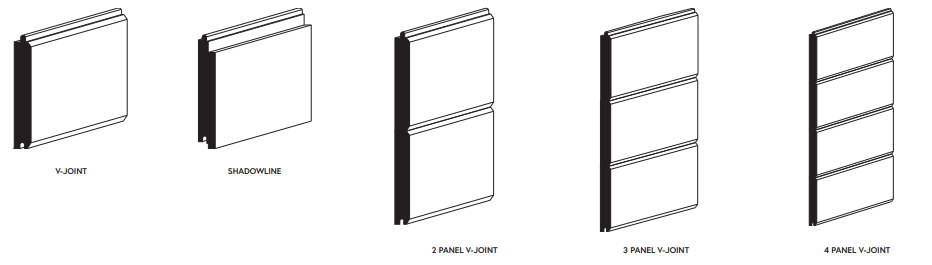

At Muskoka Timber Mills, we are committed to providing premium HDF products that cater to your project’s unique demands. We offer popular, trending profiles like Shadowline and V-Joint, available in various sizes and lengths to meet your specific needs. But we don’t stop there—if you need something more customized, we can custom mill any profile to your exact specifications, ranging from 4" to 12", offering a completely tailored solution for any project.

Whether you require the HDF blank, primed, or primed + coated, we have you covered. We’ll deliver the product in whatever finish or preparation your project demands, ensuring you get exactly what you need to make your vision a reality.

Conclusion

High-Density Fiberboard (HDF) offers unmatched durability, moisture resistance, and smooth finishes, making it the preferred choice for builders and designers alike. By offering custom milling, priming, and a variety of profiles, Muskoka Timber Mills ensures that you get a tailored product that will meet the unique needs of your project. If you’re looking for a high-performance and versatile building material, HDF is the answer.

Ready to start your next project? Contact Muskoka Timber Mills today to learn more about our HDF offerings or request a sample.